- Specially developed for the rotary blowing technology.

- Advanced testing devices are provided.

- Great flow capacity, small pressure loss, great blowing performance and long lifespan.

- Complete specifications.Two structures for choices: one with a pulse valve body and the other without.

- Great switching performance, reducing unnecessary air loss and cutting down the operating costs.

- Large valve diaphragm components of different models may be customized.Larger valves can be used as substitutes for imported products, lifetime maintenance provided.

- For each large valve, a pressure test was done and a test curve chart attached.

Description

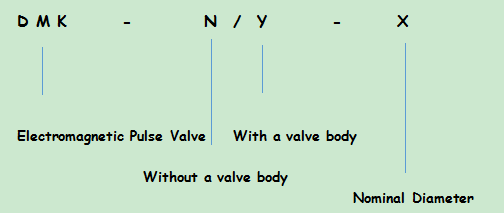

Type Definition

Specification

| No. | Type Specification | Nominal Diameter | Diaphragm | Blowing Capacity (0.1Mpa, 200ms)(under standard conditions) |

| 1 | DMF-N-150mm(6’’) | 150 | 3 | 1.6NM3 |

| 2 | DMF-N-200mm(8’’) | 200 | 3 | 2NM3 |

| 3 | DMF-N-250mm(10’’) | 250 | 3 | 2.4NM3 |

| 4 | DMF-N-300mm(12’’) | 300 | 3 | 2.7NM3 |

| 5 | DMF-N-350mm(14’’) | 350 | 3 | 3.1NM3 |

| 6 | DMF-N-400mm(16’’) | 400 | 3 | 3.5NM3 |

Technical Data

| Operating Pressure | 0.08MPa-0.15MPa |

| Air Source Medium | Clean Air |

| Protection Grade | IP65 |

| Voltage | DC24V, AC220, AC110V |

| Temperature | -25℃-120℃ |

| Ambient Temperature | -10℃-50℃ |

| Diaphragm Lifespan | One million blows or 3 years |

R&D History

- The company has began to develop large 6’’-16’’ valves since 2005;

- Trial production in 2006;

- Mass production in 2008.